Manufacturing companies have faced a seemingly endless amount of disruptions lately: COVID-19, supply chain crises, globalization challenges, rising material costs, and any other number of difficulties.

The companies that have best avoided disruptive forces have relied on their technology and processes to help them see what’s coming and avoid costly setbacks.

For instance, Custom Truck One Source embraced the digital transformation wave, substantially increasing team productivity through a better understanding of the buying cycle and real-time interests of the customer base.

Let’s take a look at what blocks effective revenue forecasting, and how digital transformation can overcome those hurdles.

Manual Processes and Outdated Technology Make Forecasting Difficult

Eighty-one percent of manufacturers say they need new approaches and tools to assist in their forecasting efforts.

Without a strong sense of your future revenue projections, it becomes a challenge to plan for costs or absorb an external disruption. The manufacturing industry has long relied on old processes and technologies. In that same survey, 95% of respondents admitted to using manual approaches for their forecasting!

When a company relies on manual approaches and old data, forecasting becomes an exercise in confirmation bias: what has always happened will always happen, regardless of the changing world outside your windows.

The Limits of Old Approaches

A McKinsey report expands on that idea: “Traditional forecasting algorithms rely on relatively simplistic statistical tools to extrapolate previous demand, based on the assumption that the relationship between independent variables (such as previous sales) and dependent variables (future demand) will likely remain unchanged.”

Most manufacturing companies rely exclusively on past performance to predict future outcomes, which can stray into gambler’s fallacy territory. “Companies usually have used only internal data, perhaps in combination with past sales trends and customer signals for future orders,” says McKinsey.

Also, the manufacturing industry has traditionally been a siloed one when it comes to planning and forecasting. “When demand forecasting and supply planning are happening independently of one another, it’s impossible to be truly efficient,” notes McKinsey.

So how does a manufacturing company overcome these challenges for better forecasting, and how does that help you avoid disruption? Keep reading to find out.

Unlock Clear Forecasting with the Data you Already Capture

B2B technology platforms have made huge strides in the last decade. If your business is still doing things the same old way then you’re putting yourself at a disadvantage. In the previous section, we described how manual processes and siloes hurt forecasting — so let’s talk about how we can shine up your crystal ball for a clearer view of the future.

Accurate forecasting really boils down to having a clear understanding of the following:

- Who your customers are (total addressable market)

- How they like to buy (what channels work best)

- When they buy (buying cycles)

The good news is that you’re already capturing all of this information and just need a way to tie it all together for that clear picture.

The Power of Buyer Intent

When one of your customers or prospects is clicking around on your website, reading research reports, or looking at your competitor’s article, they’re signaling that they might be ready to buy. In other words, they have intent.

Without the right technology in place to detect this intent, you won’t know that all of this is happening. Your customer isn’t calling you up to let you know they’re researching your new product!

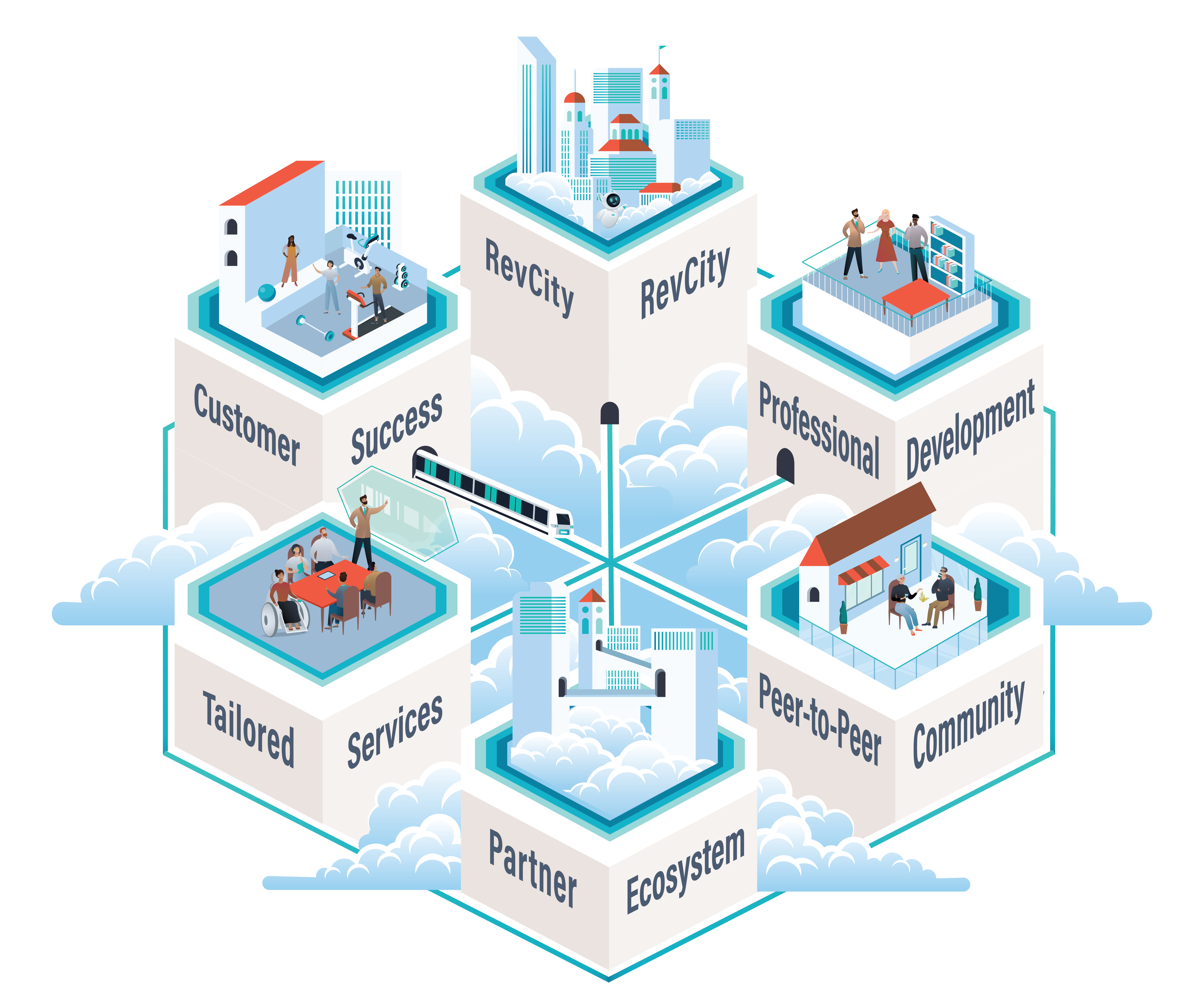

To tie together all of this information, you can leverage a digital technology platform that unveils this customer or prospect activity and gives you deeper insights into their buying journey.

Utilizing technology that reveals this data can uncover key questions such as:

- Is a customer from an account you care about reading content on your website?

- Are they researching products on your competitor’s website?

- Where are they in their buyer’s journey?

- How long are average buying cycles?

When you’ve uncovered this data, you can build reliable forecasting models that update automatically with dynamic information.

Accurate Forecasting Models Insulate Against Disruption

Instead of your operations teams performing manual calculations in ancient spreadsheets — and inputting data based on old information — this new way forward for forecasting gives your teams an automated way to report and insulate the company against unforeseen challenges.

With accurate and reliable forecasting in place, your company gains key insights into the following:

- The cost of acquiring a customer

- How many buyers are in-market

- The number of prospective customers in each stage of the buying process

- When deals are most likely to close

Accurate forecasting models help manufacturing companies prepare for disruption because they have more insights into their entire revenue stream. They can also quickly adjust when facing a challenge in a particular area of the business — whether it’s an internal problem or an outside factor.

The Future is Autonomous

McKinsey calls this style of forecasting “autonomous planning” and explains why this method is beneficial to your organization.

“Autonomous planning relies on artificial-intelligence and machine-learning algorithms, which are supplemented not only by internal data, but also by external datasets from suppliers, customers, weather forecasters, demographic sources, and broader economic indicators.”

The McKinsey paper goes on to explain why autonomous planning is the preferred path forward for forecasting:

“Incorporating these additional variables helps organizations respond to changing dynamics and external shocks more effectively. Advanced analytics can also optimize planning across the entire value chain in a way that wasn’t feasible under a siloed approach with traditional analytical tools.”

If you’re similar to most manufacturing companies and constantly analyzing threats to your business, it’s crucial to have a modern and dynamic forecasting process that gives you everything you need to shield against disruption.